It is also included in the Product Design and Manufacturing Collection license, making it a cost-effective tool for designing and modelling electronic PCBs. Contained in Fusion 360 is the PCB design suite, an incredibly powerful tool available to any business that deals with electronics. The PCB design suite is an intuitive program that allows users to draw 2D schematic drawings, automatically build a 2D PCB design and then optionally be converted to a 3D model at the push of a button. The files stay continually linked, so any changes to the schematic drawing are automatically pushed to the 2D and 3D board designs.

Schematic design

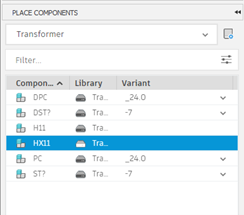

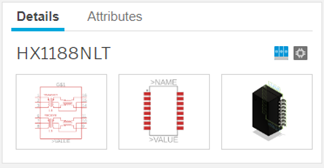

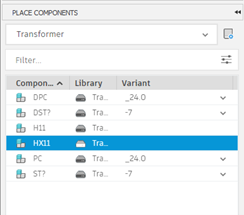

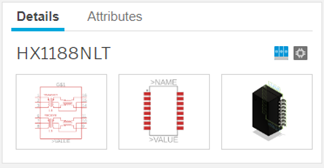

The first step in creating a complete PCB design would be to create the 2D schematic drawing; Fusion 360 makes this an easy process as they have integrated an extensive library that contains many commonly used electronic parts saving the user time. Users can add their own components to their custom libraries if a part cannot be found in the libraries. For each component, a preview is given for the schematic representation, the 2D PCB representation and the 3D model for the component.

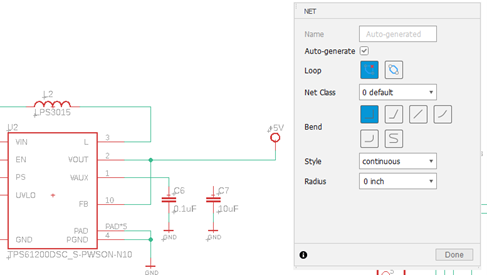

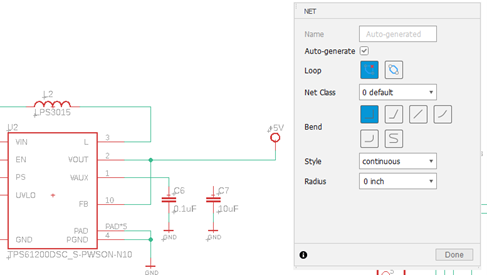

Custom title blocks can be added to the drawings to make document control and revision history seamless. All components can be linked using the NET command, which will create air wires when converted to 2D PCB, where the wiring requirements can be further refined.

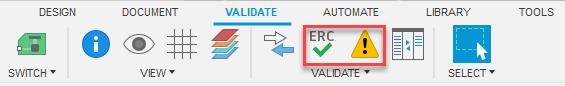

In this design stage, the user can use the ERC validation tools to check for errors and warnings related to their design. This can prevent issues from occurring at later stages of simulation and testing, meaning fewer design revisions.

2D PCB design

Once the schematic drawing has been built and checked for errors, the design can then be pushed to the 2D PCB file. The other option is to bring in a schematic file from another program, such as Eagle, which can be done by selecting the reference a schematic document command when the new electronic design is created.

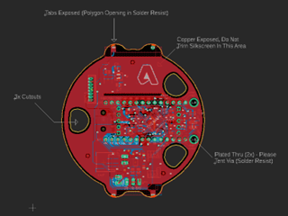

The board dimensions can be adjusted as you design to fit all the components neatly and create boards to work within pre-defined constraints. When the schematic is converted into the 2D PCB space, the components are joined with ‘air wires’, which are temporary wires that show a user what components are connected. These air wires are a placeholder before the actual wires are drawn in. Once arranged, the user can route all the wiring to fit neatly on the board and replace the air wires. There is comprehensive layer visibility when working with the 2D PCB file, which lets the user lay the wires, avoiding collisions. Users can route wires under the board and access tools to create an automatic copper pour for a signalling layer.

Testing

Users can also use the DRC (design rule checker) to set predefined clearances, distances and wire rules and run checks on the design, which will again bring any errors or warnings to their attention.

3D PCB design

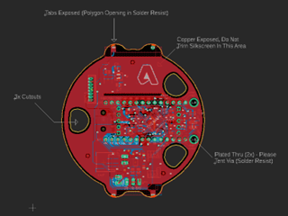

Once the 2D design is complete, users have the option to push their 2D Design to a 3D PCB file; this can be useful for the other areas of the design team as they can insert a complete to scale model int o their assemblies displaying the full detail of the PCB instead of a simplified shape. To create the 3D board, a user must select push to 3D PCB, and the file is created and ready to be exported. This process is highly efficient as the board doesn’t need in-depth modelling and can be sent out in various formats such as an Inventor .ipt file, STEP file or Solidworks file.

o their assemblies displaying the full detail of the PCB instead of a simplified shape. To create the 3D board, a user must select push to 3D PCB, and the file is created and ready to be exported. This process is highly efficient as the board doesn’t need in-depth modelling and can be sent out in various formats such as an Inventor .ipt file, STEP file or Solidworks file.

The Fusion 360 electronic design space is an easy-to-use comprehensive solution for designing your electronic PCBs. It could be cost saving to any company with Product Design and Manufacturing collection seats as it is included in this licensing. If the electronic design in Fusion 360 is something you would like to know more about, please don’t hesitate to contact us. Fill in our form and one of our Fusion 360 experts will be able to discuss your current workflows and how Fusion 360 may be used to improve them.