The following example best explains this. I will use 200MPa for yield limit for comparison purposes

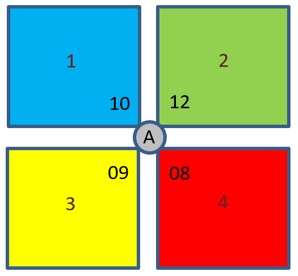

Safety factor calculation based on average stress at location A is 20.51

Average Stress value = (10+12+9+8)/4 = 9.75

Safety Factor = 200/9.75 = 20.51

Safety factor calculation based on how Nastran In-CAD displays plots at Location A is 20.97.

Safety Factor for Element 1 = 200/10 = 20

Safety Factor for Element 2 = 200/12 = 16.667

Safety Factor for Element 3 = 200/9 = 22.222

Safety Factor for Element 4 = 200/8 = 25

Average Safety Factor = (20+16.667+22.222+25)/4 = 20.97

So, this is the reason why there is a slight difference in the safety factor results. Both results are correct as they have been calculated in slightly different ways. It is entirely up to you which value you take.

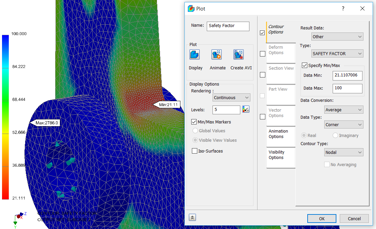

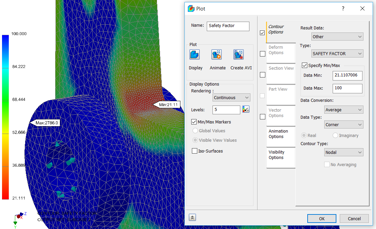

Here a safety factor display is showing a minimum value of 21.11.

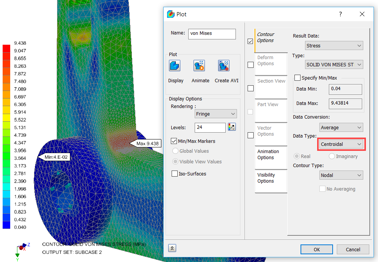

Note changing Data Type to Corner or Centroidal will yield the same safety factor result.

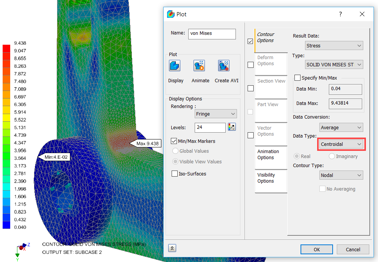

So, for the same model and results if we display the average centroidal results the maximum stress value becomes 9.4381MPa.

So, based on this value the factor of safety (hand calculation) is 21.19.

This is very close to the Safety Factor plot value of 21.11 with a difference of less than 0.5%.

I hope you have enjoyed this series. If you need any further information please complete the form.