I have been looking at the new features of Woodwork for Inventor V11 on Inventor 2021 and I must say I am pleasantly surprised. Sometimes looking at new features can be rather disappointing. Very often a new feature looks good in principle but not so good in a practical workflow.

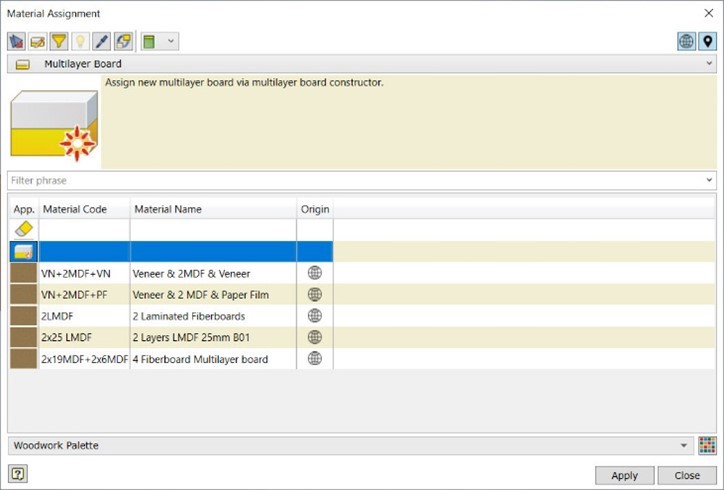

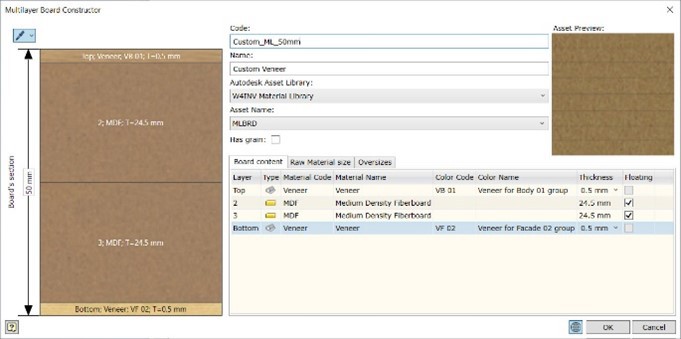

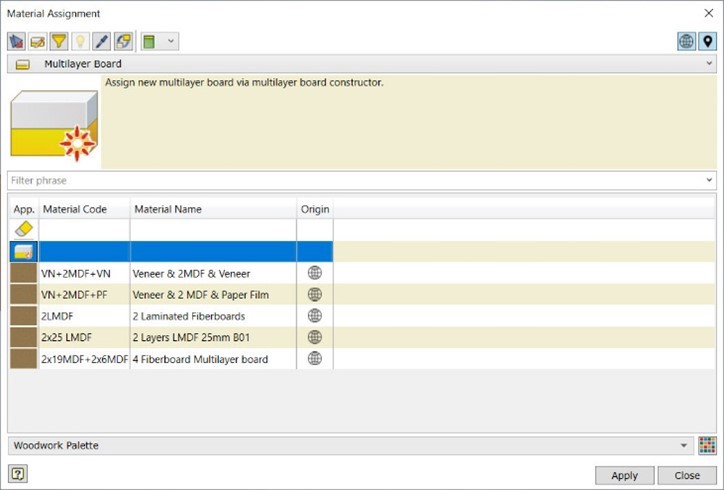

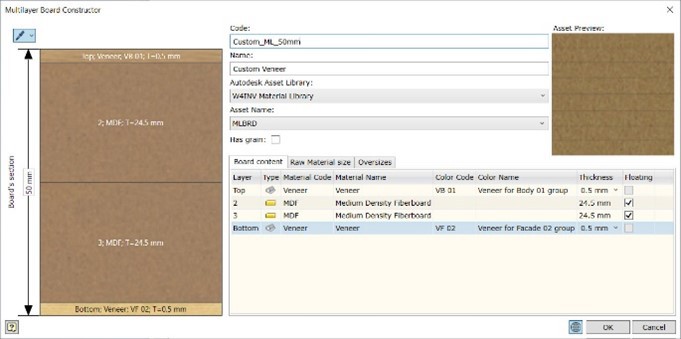

Working with materials has had a great rethink. With Woodwork for Inventor V11, we no longer need to go to the material editor then create the new material and apply as required, instead we can just go to Assign material and directly make a new multilayer board. Build up the layers with MDF and veneers. We also now have the capacity for more than one floating layer in our multilayer board.

Working with the Multilayer board constructor allows us to build for the project as we go.

We can now save this new material in the model so there is only this assembly or you are able to save to a database making it available to all projects.

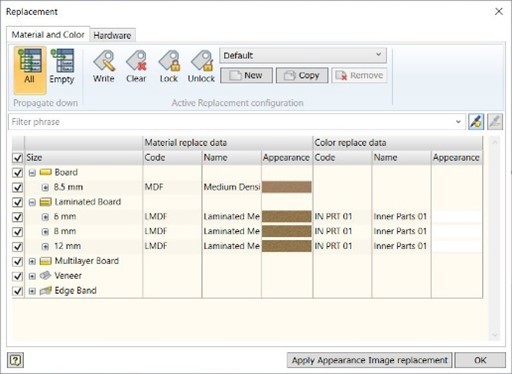

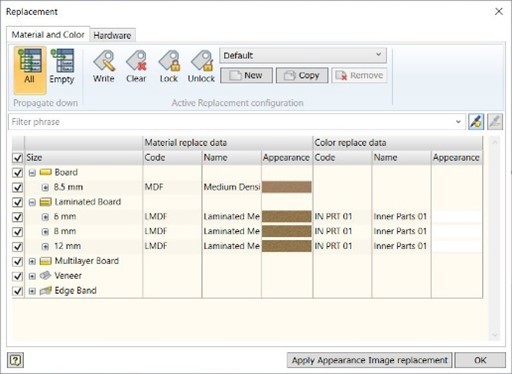

Material replacement in Woodwork for Inventor has now taken some of the confusion out of what is replaced and what is left in the model.

We have the capacity to write project materials and display the replaced material only and set colour schemes. This is excellent as we can have a display of what is actually on the model.

Very often components in Joinery are defined as length and the grain is mostly in the same direction as the components’ length. However, this is not always the case and sometimes furniture stretches, and noggin pieces are shorter in length than in thickness. Woodwork for Inventor V11 now allow us to set grain direction to the length of an object even when the length is shorter that the section width.

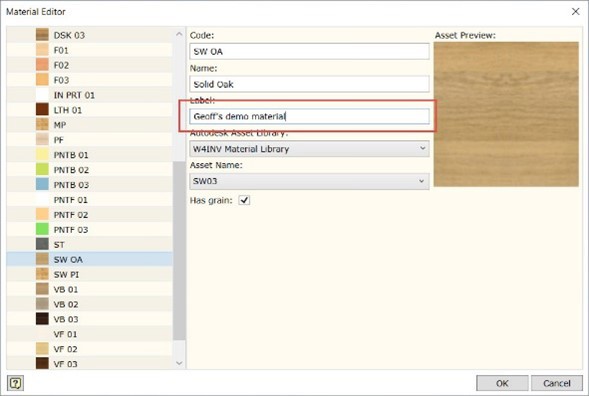

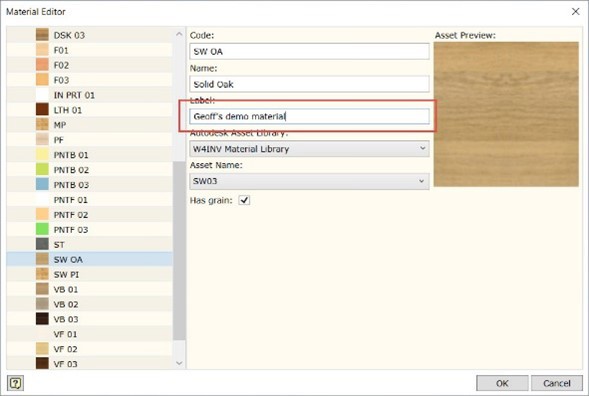

Having the capacity to label some materials is a very good addition when creating materials giving us the chance to describe its intended use or other descriptive needs in drawings and bill of materials.

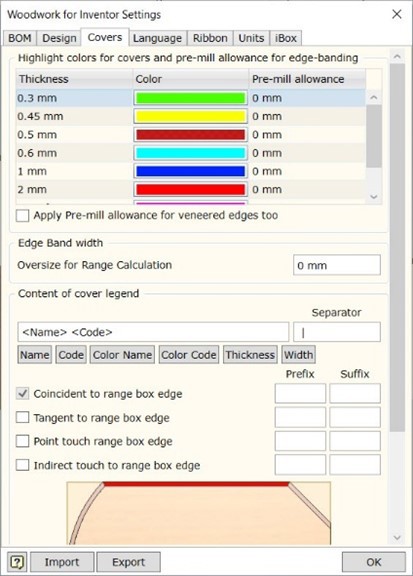

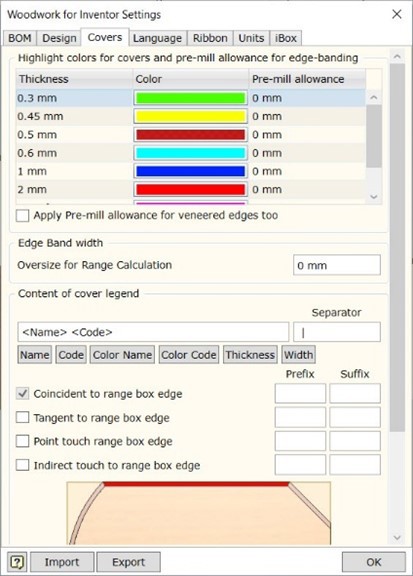

Pre-mill allowances can now be set in the design settings under covers. This will be very useful for allowance of veneers of defined thicknesses.

In iBox we are now able to define a created location in a specific sub-folder and not just as a subfolder of the parent. We can also give the components a meaningful name.

In Hardware a few new items have been added to the library. One of the features I particularly like is the new capacity to have an adaptive sculpt. In the previous versions, we added hardware, then have to rebuild the sculpt if we had to move a component. This then led us to sometimes a mismatch on dimensions because the rebuild of the sculpt removed the cut-outs and therefore the reference for the dimension. Now in V11 of Woodwork for Inventor we have an associative option so the cut-outs or holes will automatically update which would mean there is no need to do the sculpt again.

Many of the postprocessor’s have been updated and many new CNC equipment processors have been added to the assigned list.

For me coming from a woodwork background I am very pleased to see what Woodwork for Inventor have looked at for V11, particularly the materials. Creating the Multiboard builder is good and the option of Pre-Mill for veneers is really useful. Using Inventors’ associative function for hardware sculpting is going to improve the design workflow.

Woodwork for Inventor now flows seamlessly as part of Inventor and is an intrinsic set of tools for the woodworkers.

For more information on Woodwork for Inventor please have a look at our webpage: https://www.symetri.co.uk/en/Products/Woodwork-For-Inventor

Watch our webinar recordings:

Woodwork for Inventor V11 | What's New by clicking here

Woodwork for Inventor V11 | Workflows and Features by clicking here